Welcome to Asian Laser’s range of Jewellery Laser Welding Machines, engineered for jewellers who value accuracy, consistency and clean finishing in everyday work. As one of the trusted Jewellery Laser Welding Machine Suppliers in India, we bring over three decades of hands-on laser technology experience to workshops and manufacturing units across the country.

Below, you’ll find our complete catalogue of jewellery laser welding machines, each designed to meet specific production needs, material requirements, and workspace scales across the Indian jewellery industry. Explore the models to identify the solution that best fits your workflow, output goals, and level of precision required.

Book a Free Demo

Welcome to Asian Laser’s range of Jewellery Laser Welding Machines, engineered for jewellers who value accuracy, consistency and clean finishing in everyday work. As one of the trusted Jewellery Laser Welding Machine Suppliers in India, we bring over three decades of hands-on laser technology experience to workshops and manufacturing units across the country.

Below, you’ll find our complete catalogue of jewellery laser welding machines, each designed to meet specific production needs, material requirements, and workspace scales across the Indian jewellery industry. Explore the models to identify the solution that best fits your workflow, output goals, and level of precision required.

Experience That Defines Excellence

For over 30 years, Asian Laser has been at the forefront of laser solutions, designing, manufacturing and supplying advanced laser welding systems that jewellers trust. Our machines are engineered to deliver micron-level precision, reliable performance, and long-term durability, whether you’re fixing delicate gold filigree or constructing intricate custom designs.

We’re recognized among the leading jewellery laser welding machine manufacturers in India, and our legacy is grounded in hands-on innovation that empowers makers, repair specialists, and production workshops alike.

Why Choose Asian Laser for Your Jewellery Welding Needs?

1. Proven Expertise in Laser Welding Technology

With decades of experience and deep engineering know-how, we aren’t just suppliers, we’re partners in elevating your craft. Our team combines technical excellence with an understanding of real jewellery workflows in India.

2. Wide Range of Premium Machines

From compact bench-top welders to high-performance units, our portfolio covers all scales of jewellery production:

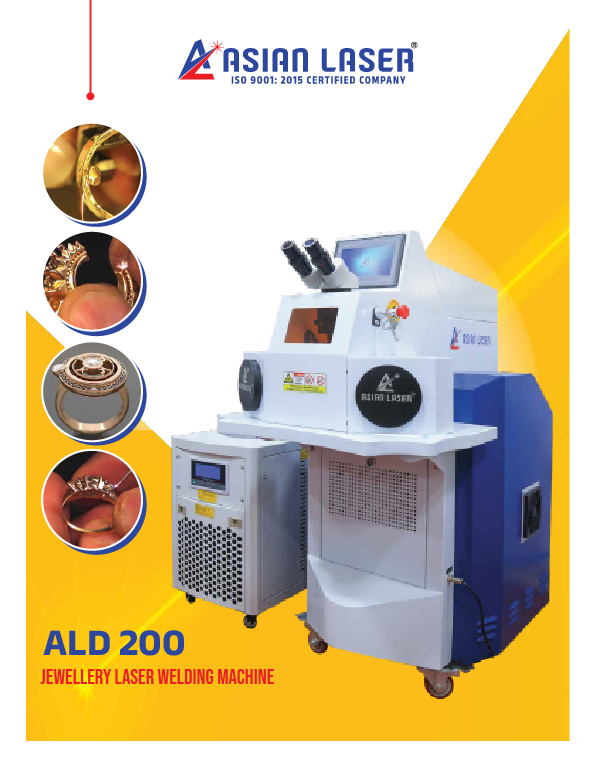

- ALD 200 – Powerful welding with stable operation and advanced safety systems.

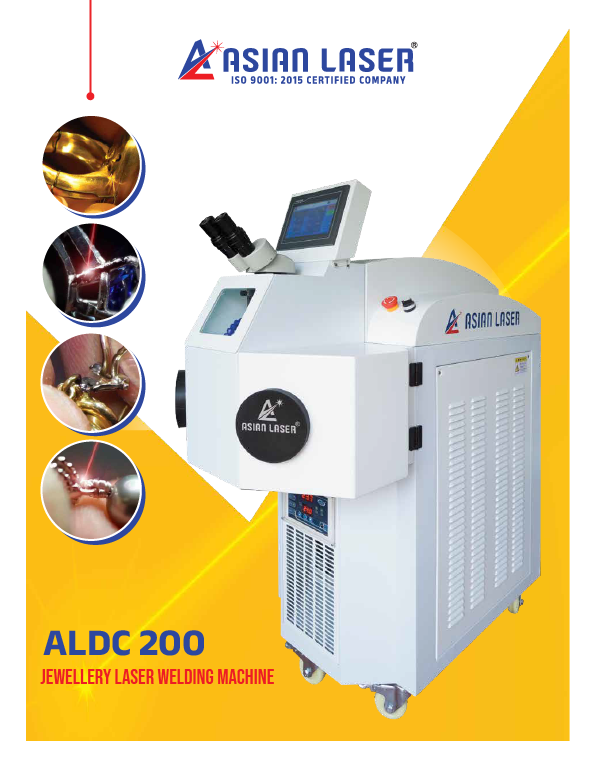

- ALDC 200 – Designed for deep, consistent welds with intelligent control and multi-metal capability.

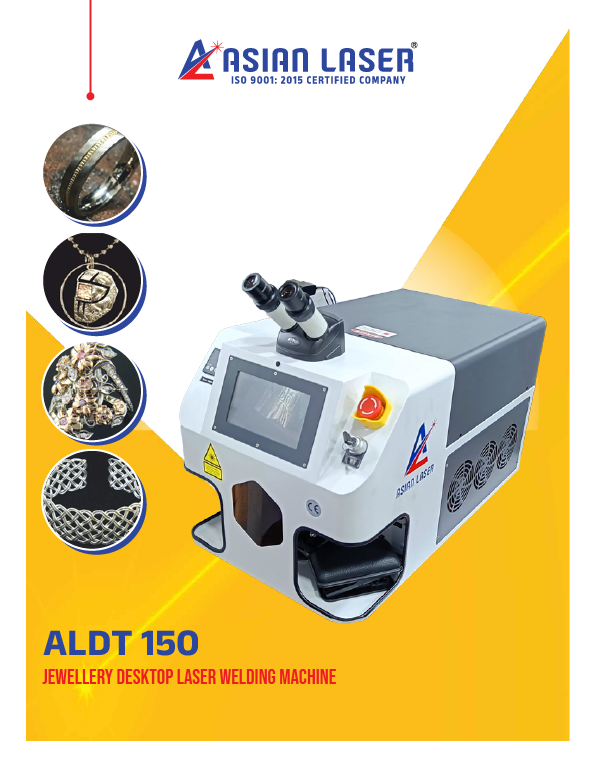

- ALDT 150 & ALFL 75 – Excellent choices for small workshops needing precision without a large footprint.

Our solutions ensure minimal distortion, reliable joints and exceptional finish every time.

3. Trusted Across India

Serving jewellery workshops in Mumbai, Delhi NCR, Jaipur, Ahmedabad, Bengaluru, and beyond, we understand the nuances of regional markets and craft expectations. Clients rely on us not just for equipment, but for long-term success and growth.

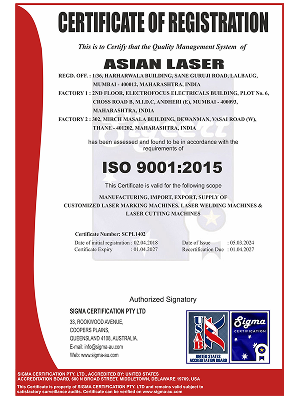

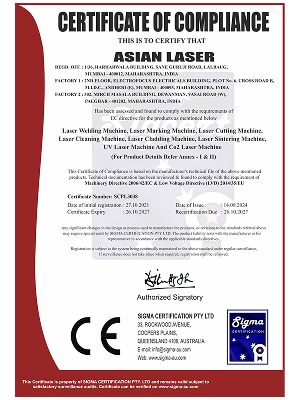

4. ISO Certified Quality Standards

Asian Laser is proud to uphold stringent quality standards, ensuring every Jewellery Laser Welding Machine we produce meets international precision and durability benchmarks.

The Asian Laser Advantage — What Sets Us Apart

Precision Meets Practicality

Laser welding reshapes how jewellery is crafted. Our machines allow welds with minimal heat-affected zones, preserving gemstones, intricate details, and original finishes.

Flexible Across Materials

Whether you are working with 18K gold, silver, platinum, or mixed metals, our systems adapt to your design needs, giving you confidence with every weld.

Training & Support

Buying a machine is just the beginning. We provide:

- On-site installation and setup

- Operator training for technicians

- After-sales support across India

This ensures your workshop stays productive from day one.

Real Success Stories — Case Studies From the Field

Crafting Heritage in Jaipur

A bespoke jeweller in Jaipur switched from traditional soldering to a gold laser welding machine supplied by us. Turnaround times dropped by 40%, and delicate work on heirlooms became significantly safer thanks to laser precision.

Modern Workflow in Mumbai

A contemporary jewellery brand in Andheri implemented our jewellery laser welder machine across its production line. They saw consistent quality improvements and reduced metal waste, boosting profits and client satisfaction.

Each of these examples reflects how the right Jewellery Laser Welding Machine Manufacturers aren’t just equipment providers, but catalysts for business transformation.

Testimonial

Choosing laser welding and laser marking solutions from Asian Laser has revolutionized our manufacturing process at Diagold. The precision and efficiency of the equipment have significantly enhanced our production capabilities. With seamless integration into our workflow, we've experienced a noticeable increase in productivity and quality.

At Mehra Die Works, the laser welding and laser marking systems from Asian Laser have exceeded our expectations. These cutting-edge tools have streamlined our processes, enabling us to deliver without compromising quality. The reliability and performance of the equipment have made it an indispensable asset in our workshop.

Implementing laser welding and laser marking technology from Asian Laser has been a game-changer for Seeds Jewellery. Thanks to this equipment's versatility and accuracy, we've pushed design boundaries. Our products now stand out with amazing detailing, from designs to flawless finishes. We're truly grateful for the transformative impact on our business.

Asian Laser's laser welding and marking solutions have revolutionized our craft at Hemfine Jewellery. With unmatched efficiency, they've enhanced both our designs and production. These systems are now indispensable to our workshop, ensuring top-notch quality and customer satisfaction.

Jewellery Laser Welding Machine — What You Gain

- Sharper Precision & Detail: Weld tiny joints without risking damage to stones or settings.

- Greater Efficiency: Complete complex joins in minutes, not hours.

- Minimal Heat Impact: Protect sensitive designs and maintain structural integrity.

Versatile Performance: Suitable for repairs, custom work, and full-scale manufacturing.