Why Partnering with the Right Laser Welding Machine Manufacturer Matters for Your Business

Introduction: Precision Meets Business Growth

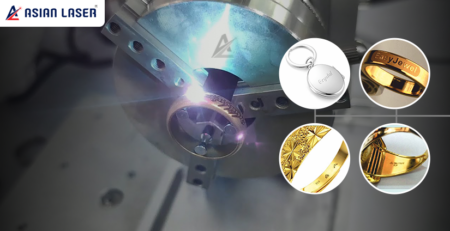

In industries like jewelry, electronics, automotive, and medical devices, laser welding machines have become essential tools for achieving precision, durability, and efficiency. But here’s the catch,the quality of your welding machine is only as good as the manufacturer behind it. Choosing the right laser welding machine manufacturer can directly impact your production quality, operating costs, and long-term business growth.

Trusted companies like Asian Laser, a leading manufacturer in India, provide cutting-edge laser welding solutions tailored to industries that demand accuracy and reliability. In this blog, we’ll explore why partnering with the right manufacturer makes all the difference and the key benefits it brings to your business.

1. Assurance of Cutting-Edge Technology

When you choose a reputable manufacturer, you gain access to the latest laser welding technology. Advanced features like high beam quality, stable power output, and precision control ensure that welds are strong, clean, and aesthetically appealing.

For instance, Asian Laser ALD 200 Jewelry Welding Machine is specifically designed for gold and silver repairs, delivering unmatched precision that smaller, generic machines cannot match.

Takeaway: By working with a trusted manufacturer, your business stays ahead with the latest innovations and enhanced productivity.

2. Customized Solutions for Different Industries

Not every industry has the same welding needs. Jewelry manufacturers require ultra-fine welds for delicate designs, while the automotive sector demands high-strength welding for critical components.

A reliable manufacturer understands this difference and offers tailored machines. Asian Laser, for example, provides laser welding machines for jewelry, medical tools, and precision engineering, ensuring businesses get solutions designed for their exact requirements.

Takeaway: Customization leads to higher efficiency and less wastage, directly boosting profitability.

3. Consistency and Quality in Output

Cheap or poorly manufactured machines may work initially but often fail to maintain consistent quality. Uneven welds, overheating, and frequent breakdowns can stall production and damage your brand’s reputation.

By partnering with an experienced manufacturer, you gain machines tested for quality, durability, and long-term stability. Asian Laser’s machines, for instance, are known for their repeatable accuracy and minimal maintenance, ensuring consistent output even in high-volume production.

Takeaway: Consistency in welding quality builds customer trust and reduces costly reworks.

4. After-Sales Support and Training

Buying a laser welding machine isn’t a one-time transaction. The right manufacturer provides after-sales support, operator training, and easy access to spare parts. This ensures your team can fully utilize the machine’s potential without facing frequent downtimes.

Asian Laser is well-regarded for its technical support and training programs, making it easier for businesses to onboard new technology quickly.

Takeaway: Strong after-sales service reduces operational headaches and increases ROI.

5. Cost Efficiency in the Long Run

At first glance, cheaper welding machines from unknown sources might seem attractive. But in reality, poor-quality machines lead to frequent breakdowns, higher energy consumption, and costly repairs.

With a trusted manufacturer, the initial investment may be slightly higher, but the long-term savings in efficiency, durability, and reduced downtime make it worthwhile.

Takeaway: Think of a laser welding machine as a long-term partner in your production, not just a one-time expense.

6. Compliance with Safety and Quality Standards

Industries like jewelry and medical equipment demand compliance with international safety and quality standards. The right manufacturer ensures machines are built with safety features, user-friendly controls, and compliance certifications.

Asian Laser integrates ergonomic designs, energy efficiency, and compliance with global welding standards, helping businesses maintain credibility with clients and regulators.

Takeaway: Compliance isn’t optional, it’s crucial for brand reputation and market trust.

7. Scalability for Business Growth

As your business grows, your production demands will evolve. A reliable manufacturer not only provides the right machine today but also supports future scalability with upgrades and advanced models.

Asian Laser offers a wide range of laser welding and marking machines, giving businesses flexibility to expand without switching to a new vendor.

Takeaway: A long-term partnership ensures smooth scalability and reduces transition costs.

Conclusion: The Right Manufacturer is a Growth Partner

Choosing the right laser welding machine manufacturer isn’t just about buying a piece of equipment—it’s about securing a partner for your business success. From cutting-edge technology and consistent output to after-sales support and cost efficiency, the benefits are undeniable.

By working with trusted names like Asian Laser, you ensure that your welding solutions meet the highest standards of precision, durability, and reliability, helping your business grow stronger in competitive markets.

FAQs

Q1: Why is choosing the right laser welding machine manufacturer important?

Because a reliable manufacturer ensures cutting-edge technology, consistent quality, better support, and long-term cost efficiency.

Q2: What industries benefit most from laser welding machines?

Industries like jewelry, electronics, automotive, and medical devices benefit the most due to their need for precision and durability.

Q3: What makes Asian Laser a trusted manufacturer?

Asian Laser offers advanced technology, customized solutions, strong after-sales support, and compliance with international standards.

Q4: How does after-sales support impact ROI?

Good after-sales service ensures smooth operations, reduces downtime, and maximizes machine efficiency, improving ROI.

Q5: Are customized welding solutions better than generic ones?

Yes, customized solutions ensure machines meet industry-specific needs, leading to higher efficiency and lower wastage.