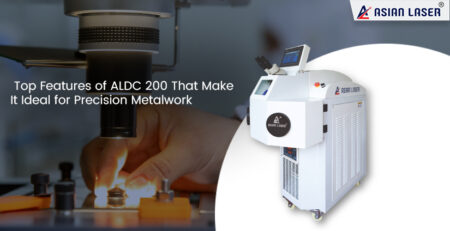

What Makes the ALFL 75 Jewellery Welding Machine Ideal for Gold & Silver Repairs?

The ALFL 75 Jewelry Welding Machine is a compact, maintenance-free, and highly precise laser welder designed specifically for delicate gold and silver repairs. Its pinpoint laser beam minimizes heat impact, prevents deformation, and produces seamless, strong welds even near gemstones. With multi-metal compatibility, customizable settings, 24-hour operation capability, and built-in light shielding for safety, it delivers both performance and reliability—making it an ideal choice for jewelers seeking efficiency and flawless results.

1. Precision Where It Matters Most

1.1 Ultra-focused Laser Minimizes Thermal Impact

The ALFL 75 uses a high-intensity, concentrated laser beam that delivers pinpoint accuracy. This is essential when repairing fragile gold or silver components, ensuring the surrounding area remains unaffected even near sensitive gemstones.

1.2 No Deformation for Delicate Repair Work

Delicate restoration—like fixing fine filigree or tiny clasps—demands unwavering accuracy. The ALFL 75 excels here, producing repairs that maintain the jewelry’s original shape without warping.

2. Compact & Ergonomically Designed for Showrooms

Showroom or atelier space can be scarce. The ALFL 75’s compact design allows it to fit comfortably while still housing robust internal systems for cooling and power—no bulky external attachments needed.

3. Maintenance-Free with Long Lifespan

One of the standout advantages is its maintenance-free build. Designed to withstand the demands of daily use without frequent servicing, the ALFL 75 promises longevity and consistent performance.

4. Versatile Metal Compatibility for Diverse Jewellery Needs

Whether it’s gold or sterling silver—or even platinum or titanium—the ALFL 75 supports an array of precious metals. This versatility makes it ideal for gold and silver repairs, especially in mixed-metal repair workflows.

5. High-Control Interface & Custom Settings

The machine features an intuitive interface (often touchscreen-based) that lets you adjust laser power, pulse duration, frequency, and focus depth, and even save presets for repeat tasks—boosting both precision and efficiency.

6. Built for Efficiency—Low Thermal Distortion & Energy Cost

Minimal thermal impact isn’t only about reducing damage—it also means less energy waste. The ALFL 75 combines energy efficiency with exceptional weld quality, offering long-term savings for jewelry repair businesses.

7. Strong Weld Strength with Pristine Finish

The ALFL 75 delivers firm, reliable weld joints that look seamless—no excess residue or discoloration. This ensures that cosmetic repairs on gold or silver look top-tier without additional finishing.

8. 24-Hour Operation for Maximum Productivity

For busy workshops, stamina matters. The ALFL 75 is built for continuous operation, enabling high-volume workflow without performance drops—a true productivity enabler.

9. Safety-First Light Shielding

Precision and safety go hand in hand. Advanced light shielding protects operators from laser exposure, reinforcing both productivity and safety during delicate repair sessions.

10. Reliable After-Sales Support from Asian Laser

As an ISO-certified (9001:2015) provider with decades of experience, Asian Laser backs its machines with installation assistance, training, and round-the-clock service—minimizing downtime and optimizing customer experience.

Summary: Why ALFL 75 Stands Out for Gold & Silver Repairs

Feature

Benefit

Pinpoint laser & low heat

Precision repairs near gemstones without damage

Compact and ergonomic

Ideal for showroom and small workshop settings

Maintenance-free durability

Lower long-term upkeep and reliable uptime

Multi-metal compatibility

Versatile use across gold, silver, and more

Customizable interface

Tailored workflow and saved settings

Energy-efficient operation

Cost-effective welding with a clean finish

Continuous 24-hour operation

Handles full-day workloads without faltering

Light shielding safety

Protects the user during delicate procedures

Comprehensive support

Fast service, training, and peace of mind

FAQs

-

Can the ALFL 75 weld both gold and silver effectively?

Yes—it’s optimized for precious metals, including gold, silver, platinum, and more, making it ideal for diverse jewelry repairs.

-

Is this machine suitable for small workshops?

Absolutely—its compact footprint, ease of use, and maintenance-free design make it well-suited for boutique or showroom environments.

-

Does it require frequent maintenance?

No—the ALFL 75 is specifically designed to be maintenance-free, providing dependable operation with minimal upkeep.

-

Is it safe to operate over long hours?

Yes—the machine is engineered for 24-hour continuous operation and includes advanced light shielding to protect operators.

-

Who provides support and training for the machine?

Asian Laser offers full assistance, including installation, user training, and 24/7 support backed by their ISO-certified expertise.