What Industries Will Benefit Most from Laser Engraving Machines in 2025?

Laser engraving technology has come a long way, revolutionizing how we mark, cut, and engrave a wide range of materials. As we move into 2025, we can expect to see even greater adoption of laser engraving machines across various sectors. Let’s explore some of the industries that will benefit most from this cutting-edge technology.

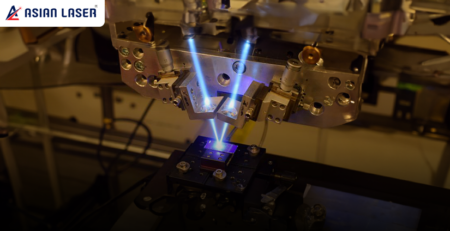

- The Electronics Industry:

The electronics industry is constantly evolving, with smaller and more complex components becoming the norm. Laser engraving machines play a crucial role in this sector by:

- Precise marking: Laser marking allows for the permanent and highly accurate marking of electronic components, including serial numbers, barcodes, and logos. This is essential for traceability, inventory management, and quality control.

- Fine cutting: Lasers can cut intricate shapes and patterns in delicate electronic components with minimal heat-affected zones, reducing the risk of damage.

- Micromachining: Laser technology enables the creation of micro-features on electronic components, such as vias and connectors, for advanced applications.

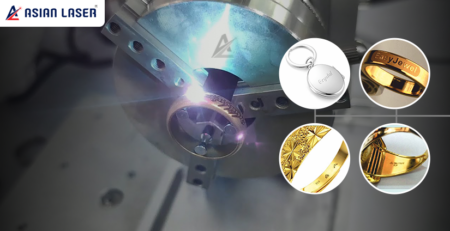

- The Jewellery Industry:

The jewellery industry is renowned for its intricate designs and personalized creations. Laser engraving machines are transforming jewellery manufacturing in several ways:

- Personalized jewellery: Lasers can quickly and precisely engrave custom messages, names, and dates onto rings, necklaces, and bracelets, adding a unique touch to each piece.

- Intricate designs: Laser engraving allows for the creation of intricate and detailed designs on jewellery, including filigree, lace patterns, and delicate motifs.

- Hallmarking: Laser engraving machines are used for hallmarking jewellery, ensuring authenticity and compliance with industry standards.

- The Automotive Industry:

The automotive industry relies heavily on precision and efficiency. Laser engraving machines offer several advantages in this sector:

- Part marking: Lasers can mark vehicle parts with unique identification numbers, logos, and other crucial information for traceability and quality control.

- Cutting and shaping: Lasers can cut and shape various automotive components with high precision and speed, improving manufacturing efficiency.

- Surface treatment: Lasers can be used to create textures and patterns on automotive surfaces, enhancing aesthetics and improving functionality.

- The Healthcare Industry:

The healthcare industry demands high levels of precision, hygiene, and sterility. Laser engraving machines offer several advantages in this critical sector:

- Medical device marking: Lasers can permanently mark medical devices with unique identification numbers, sterilization dates, and other essential information.

- Surgical instrument customization: Lasers can personalize surgical instruments with surgeon names or hospital logos, improving inventory management and reducing the risk of cross-contamination.

- Prosthetic and orthopedic applications: Lasers can be used to create customized prosthetics and orthopedic implants, improving patient outcomes.

- The Manufacturing Industry:

The manufacturing industry encompasses a wide range of sectors, from aerospace to food processing. Laser engraving machines offer numerous benefits across this diverse landscape:

- Tool and die marking: Lasers can mark tools and dies with identifying information, ensuring traceability and reducing the risk of mix-ups.

- Metal fabrication: Lasers can cut, weld, and mark various metals with high precision and speed, improving manufacturing efficiency.

- Food processing: Lasers can be used for non-contact marking of food products, ensuring food safety and traceability.

Choosing the Right Laser Engraving Machine:

Selecting the appropriate laser engraving machine for your specific industry and application is crucial. Factors to consider include:

- Material compatibility: Different laser types are suitable for different materials.

- Marking speed and accuracy: The required speed and accuracy will vary depending on the application.

- Machine size and footprint: The available space in your facility will determine the size of the machine you can accommodate.

- Budget: Laser engraving machines come in a wide range of prices to suit various budgets.

Why Choose Asian Laser?

At Asian Laser, we are a leading provider of high-quality laser engraving machines in India. Our machines are known for their reliability, precision, and ease of use. We are an ISO-certified company with a strong commitment to quality and customer satisfaction. Our machines also comply with CE standards, ensuring safety and reliability.

Laser engraving machines are poised to play an increasingly important role in a wide range of industries in 2025 and beyond. Their versatility, precision, and efficiency make them invaluable tools for marking, cutting, and personalizing a variety of materials. By carefully considering your specific needs and choosing the right machine, your business can leverage the power of laser technology to achieve greater productivity, efficiency, and profitability.

FAQs:

- What are the different types of laser engraving machines?

- Common types include CO2 lasers, fiber lasers, and YAG lasers, each with its own strengths and weaknesses.

- What materials can be engraved with laser machines?

- Lasers can engrave a wide range of materials, including metals, plastics, wood, glass, and even some ceramics.

- Is laser engraving safe?

- When used properly, laser engraving is a safe process. However, it is essential to follow safety guidelines and wear appropriate protective gear.

- What is the typical lifespan of a laser engraving machine?

- With proper maintenance, laser engraving machines can last for many years.

- Can I learn to operate a laser engraving machine myself?

- Yes, most laser engraving machines are relatively easy to operate and come with user-friendly software and manuals. However, it is always recommended to receive proper training from a qualified technician.

By incorporating laser engraving machines into your production processes, you can gain a competitive edge, improve product quality, and enhance customer satisfaction.