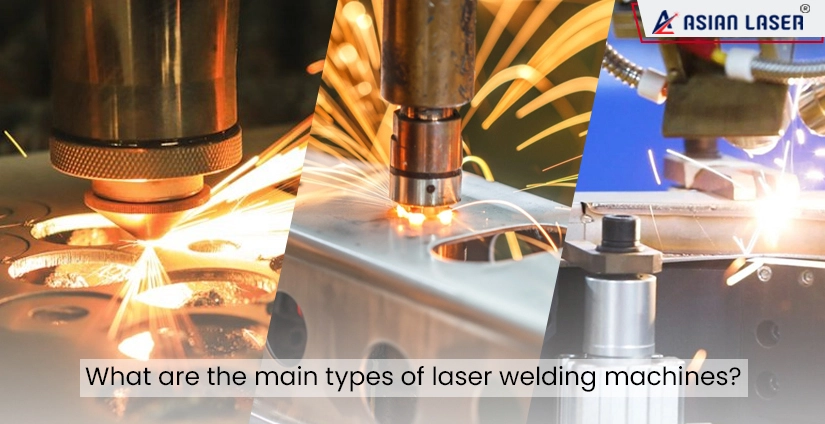

What are the main types of laser welding machines?

Industrial manufacturing constantly changes, and laser welding machines are essential for precision and efficiency. These advanced devices use the power of lasers to join materials with unmatched accuracy and speed. However, what are the primary types of laser welding machines and how do they vary? Let’s explore this exciting field to uncover the answers.

Understanding Laser Welding Machines

Before we discuss the types, let’s understand the fundamentals of laser welding machines. Essentially, these machines employ high-intensity laser beams to melt and fuse materials. The process involves directing a focused beam of light onto the workpiece, generating heat that causes the material to melt and form a bond when cooled.

Fiber Laser Welding Machines

The fibre laser variety is one of the most prevalent types of laser welding machines. These machines utilize optical fibers to deliver the laser beam to the workpiece, offering exceptional precision and versatility. Fiber laser welding machines are renowned for their ability to weld various materials, including metals, plastics, and composites, with minimal heat-affected zones.

CO2 Laser Welding Machines

Another prominent category is CO2 laser welding machines, which employ carbon dioxide gas as the laser medium. These machines are particularly adept at welding thicker materials and are commonly used in applications requiring deep penetration welds. They are prized for their high power output and cost-effectiveness, making them a popular choice across various industries.

Diode Laser Welding Machines

Diode laser welding machines are compact, energy-efficient, and suitable for certain applications. They use semiconductor diodes to generate the laser beam, which allows for precise control and minimal maintenance requirements. They are preferred for their portability and are well-suited for automated processes.

Choosing the Right Laser Welding Machine

When choosing a laser welding machine, several factors must be considered to ensure that it meets your specific needs. You must take into account the type of materials you will be working with, the level of precision you require, and the volume of production. In addition, you should consider factors such as ease of operation, maintenance requirements, and after-sales support to make an informed decision.

Top Laser Cutting Machine Manufacturers in India

In India’s vibrant manufacturing landscape, several companies stand out for their excellence in producing laser-cutting machines. Some top manufacturers include top laser cutting machine manufacturers in India, renowned for their innovative technology and reliable performance. These manufacturers offer diverse laser-cutting solutions tailored to various industries and applications.

Laser Engraving Machine Supplier in India

Many suppliers in India cater to diverse requirements for laser engraving machines. Whether you’re seeking high-speed engraving capabilities or intricate detail work, laser engraving machine suppliers in India offer a wide selection of cutting-edge solutions. These suppliers are committed to delivering quality products backed by comprehensive service and support.

Conclusion

Laser welding machines are essential to modern manufacturing, offering unmatched precision, efficiency, and versatility. Different types of laser welding machines are available, such as fiber laser, CO2, and diode laser, each with unique strengths. Understanding the differences between these machines and selecting the appropriate one for your requirements can help you enhance your production capabilities significantly. In the dynamic Indian manufacturing landscape, it’s crucial to rely on top laser cutting machine manufacturers and laser engraving machine suppliers to gain access to the latest advancements and superior quality. So, embrace the power of laser welding technology and unlock a world of possibilities for your business.