How to Choose the Right Laser Welding Machine for Your Industry in 2025

In 2025, industries across the nation are increasingly relying on advanced tools to meet the demands of precision and efficiency. Among these tools, the Laser Welding Machine is a critical component in manufacturing processes. Whether you’re in the jewellery sector, automotive industry, or medical device manufacturing, selecting the right laser welding machine can significantly impact your productivity and quality.

With the Laser Welding Machine Market projected to grow rapidly due to increasing automation and demand for high-precision welding, it’s essential to understand what makes a laser welding machine suitable for your specific needs. Let us explore key considerations for choosing the ideal machine, with a special focus on industries like jewellery manufacturing.

Understanding Laser Welding Machines

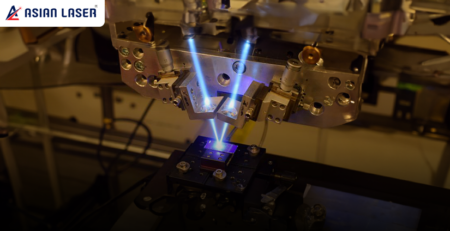

A Laser Welding Machine is a device that uses laser beams to join metals or thermoplastics. The laser creates a concentrated heat source, enabling fine, clean, and accurate welds. Its applications span multiple industries, including jewellery, electronics, automotive, and even dental.

With the rising Laser Welding Machine demand, many businesses are turning to this technology to achieve seamless and efficient production. For example, Jewelry Laser Welding Machines have become indispensable for creating intricate designs and repairing precious pieces without damaging the surrounding material.

Key Factors to Consider When Choosing a Laser Welding Machine

Selecting the right laser welding machine for your industry involves evaluating various factors. Here’s a breakdown of what you need to consider:

Purpose and Application

The first step is identifying your specific needs. Are you looking for a machine to weld delicate jewellery or something more robust for automotive components? If you’re in the jewellery industry, a Jewelry Laser Welding Machine is ideal for working with precious metals. Trusted Jewellery Laser Welding Machine Suppliers in India, like Asian Laser, offer CE certified and ISO-standard machines designed for precise and intricate tasks.

Power Requirements

Laser welding machines come in various power ranges, typically measured in watts. For delicate applications like jewellery, machines with lower power are sufficient, whereas industrial uses may require higher wattage for thicker materials.

Machine Type

There are different types of laser welding machines, including:

- Fiber Laser Welding Machines: Known for high efficiency and durability.

- Pulsed Laser Welding Machines: Ideal for precision tasks like jewellery.

- Continuous Wave Laser Machines: Best suited for high-speed industrial operations.

Understanding which type aligns with your industry needs is crucial.

Ease of Use

An easy-to-operate machine can save training time and minimize errors. Look for features like user-friendly interfaces, automatic settings, and comprehensive manuals. Companies like Asian Laser provide machines that are both advanced and simple to use.

Cost Efficiency

While investing in a Laser Welding Machine may seem expensive initially, it’s essential to evaluate the long-term benefits. Machines with low maintenance, energy efficiency, and high durability can save costs over time.

After-Sales Support and Maintenance

Choose a supplier that offers robust after-sales support, including training, maintenance, and quick resolutions to technical issues. Asian Laser, a leading brand in Mumbai, ensures reliable customer support and high-quality machines.

Certification and Standards

Always check for certifications like ISO standards, CE certified, which indicate compliance with international quality and safety norms. Asian Laser offers machines that meet these standards, ensuring reliability and performance.

Industry-Specific Considerations

Different industries have unique requirements when it comes to laser welding. Here’s a closer look:

Jewelry Industry

For intricate designs and repairs, Jewelry Laser Welding Machines are indispensable. They enable precision welding without affecting the surrounding areas, preserving the beauty and integrity of the piece. Asian Laser is a trusted name among Jewellery Laser Welding Machine Suppliers in India, offering top-notch machines tailored for jewellers.

Automotive Sector

The automotive industry requires machines capable of handling larger components and thicker materials. Asian laser welding machines are popular in this sector due to their strength and speed.

Medical Device Manufacturing

Precision is non-negotiable in the medical field. Laser welding is used for devices like surgical tools and implants, where exactness and cleanliness are critical.

Electronics Industry

Compact designs and delicate components make laser welding a preferred choice for electronic manufacturing. The ability to create precise welds without causing heat damage is a significant advantage.

Benefits of Using Laser Welding Machines

Laser welding machines are a game-changer for industries due to their numerous advantages:

- High Precision: Ideal for intricate designs and delicate materials.

- Efficiency: Reduces production time with faster welds.

- Durability: Creates strong, reliable bonds.

- Cost-Effective: Minimizes material wastage and energy consumption.

- Versatility: Suitable for various materials and industries.

Choosing the right Laser Welding Machine for your industry in 2025 is a decision that requires careful thought and research. By understanding your application, power requirements, and budget, you can select a machine that enhances your production processes and delivers consistent quality.

With the growing Laser Welding Machine Market, investing in a high-quality, certified machine like those offered by Asian Laser ensures you stay ahead of the competition. Whether you’re looking for a Jewelry Laser Welding Machine or a versatile machine for industrial applications, Asian Laser’s CE-certified and ISO-standard machines are designed to meet your needs.

Make the right choice today to set your business on the path to success in 2025 and beyond.

FAQs

- What industries use laser welding machines?

Laser welding machines are used in various industries, including jewellery, automotive, electronics, aerospace, and medical device manufacturing. - What is the difference between fibre laser and pulsed laser welding machines?

Fibre lasers are best for high-speed, heavy-duty tasks, while pulsed lasers are ideal for precision applications, such as jewellery welding. - Why are CE certifications and ISO standards important for laser welding machines?

These certifications ensure that the machine meets international quality and safety standards, providing reliability and performance. - What should I look for in a jewellery laser welding machine?

Precision, low power consumption, and ease of use are essential. Ensure you buy from reputable Jewellery Laser Welding Machine Suppliers in India, like Asian Laser. - How does laser welding compare to traditional welding?

Laser welding offers greater precision, less heat damage, faster operation, and the ability to work with delicate materials compared to traditional methods.

By understanding the considerations above and exploring options from trusted suppliers like Asian Laser, you can confidently invest in a laser welding machine that meets your business goals.