An ultimate guide in finding the ideal laser cutting machine

In recent years, many manufacturers are buying an industrial laser cutting machine as it is a significant investment. It isn’t just the initial price you pay, but the fact is that the acquisition will have a considerable impact on the whole manufacturing process. If the incorrect equipment is chosen, you have to face the problem for your entire cutting process, while if you choose the right, it could be long-lasting and profitable for your business.

Perhaps the serious question is, “Should I even buy a laser cutting machine?”

This guide will assist you in making a capital purchase decision which will drive your manufacturing operations to new heights.

1. The range of materials and business requirements that the Enterprise Processes

First, we’ve to think clearly about the business space, the thickness of cutting elements, which elements got to be cut, and other factors. Once all these factors are done, choose the dimensions of the facility of the equipment to be acquired. Therefore, the manufacturers can customise the features of the worktable as per the customer requests.

2. Select a reputed integrated within the industry

Understand the strength, machine parameters and merchandise quality, performance of laser cutting machine. Laser cutting machine is an in-depth line of kit once you pop out. You would like to take care while selecting the right integrator who has the strength and price concessions to speak and proofing within the early stage who also provides the training of the device.

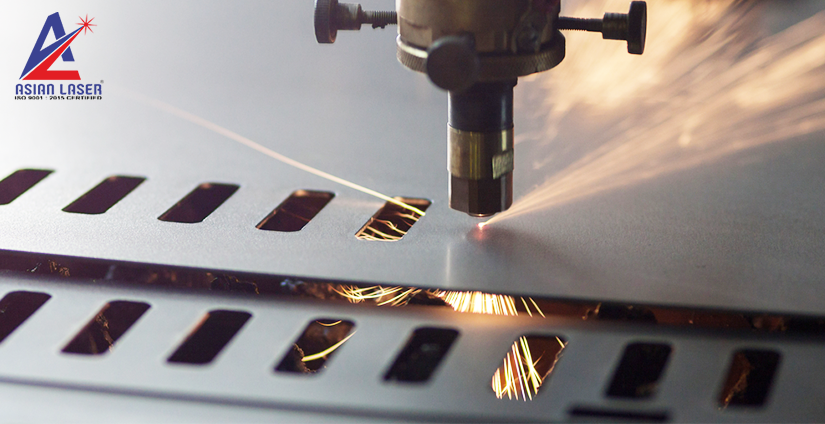

3. The backbone of a laser cutter

Laser cutting machines have some critical parts, and we should know everything about it before buying. Like laser generators, laser cutting heads, servo motor, Guide Rail, the cistern, and so on. As these parts directly affect the laser cutting machine, cutting speed and accuracy.

4. Select a brand with excellent after-sales service

Each manufacturer’s after-sales service is tremendously different. The span of the warranty is additionally uneven. Asian Laser provides customers with day-to-day maintenance programs, machine and laser software, our highly-skilled professionals give training to our customers at the time of installation, for machine operation and software as soon as possible. Our prompt and instant 24×7 service drives us to be the leader in the Laser industry. Asian Laser, a leading laser welding systems integrator in India, we provide immediate maintenance services and carry out repair work for the customer with the least downtime.

In short, buying laser cutting machines for business may be a significant investment, and therefore you save a lot by choosing the right integrator and generating more revenue through it. However, an appropriate laser cutting machine can bring high production efficiency, cost savings. Can bring benefits to the enterprise, then the first investment is worthwhile.

Asian Laser offers advanced engraving, cutting, marking, and industrial laser welding machines in India. We cover the full dynamism series of laser cutting operations, laser welding systems, laser marking scale, texturing machine, heat treatment systems, drilling machines, laser devices, all kinds of support materials, laser processing, and many more laser machining tools. We are involved in the installation, training, repair, and preventive maintenance of laser machines used in various industries. We are the leading medicine, engineering, solar energy, and jewellery laser welding machine suppliers in India. Our services reach all over India, Sri Lanka, and Saudi Arabia. Currently, we operate out of our three offices in Mumbai. As a pioneer and a leading laser marking, engraving, and laser welding machine operators in India, our professionals are the masters of the devices that we handle. We deliver quick and instant service for our clients to meet their requirements.

To know more visit: https://asianlaser.in/