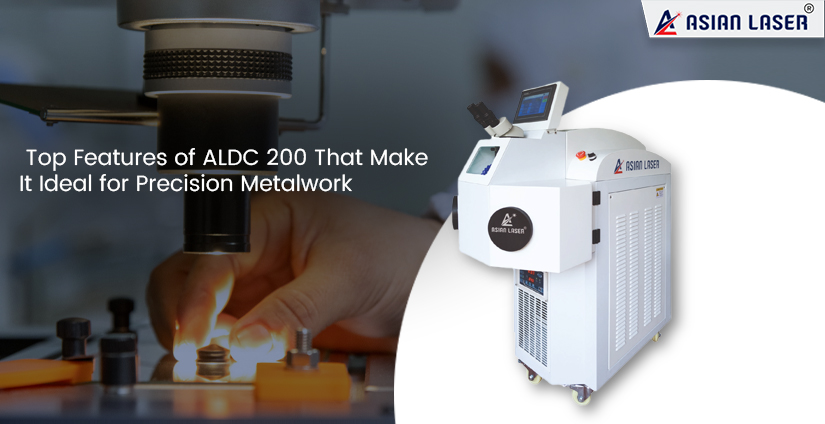

Top Features of ALDC 200 That Make It Ideal for Precision Metalwork

The ALDC 200 is a high-precision laser welding machine engineered for intricate metalwork, offering minimal heat impact, zero deformation, and deep, durable welds across a wide range of metals. Built for 24-hour continuous operation, it combines accuracy with versatility, making it ideal for industries from jewelry and electronics to automotive and healthcare. With low maintenance needs, advanced safety features, and strong after-sales support, it delivers reliable, efficient, and flawless results for precision manufacturing.

1. Laser-Driven Precision: Less Heat, Maximum Control

1.1 Minimizes Heat-Affected Zone

One of the most compelling advantages of the ALDC 200 is its ability to confine thermal energy precisely where you need it. By minimizing the heat-affected zone, this machine preserves the structural integrity of delicate workpieces—a critical feature when working with thin or intricate components.

1.2 Ensures Zero Deformation

Even under extended use, the ALDC 200 leaves no distortion. This precision is especially vital in applications like jewelry or medical device fabrication, where component shape integrity is non-negotiable.

2. Deep and Durable Welds

The ALDC 200 doesn’t just weld—it creates robust, deep fusion that lasts. Its pulses penetrate thoroughly, forming a weld that’s both strong and resilient. This is essential in sectors where joint integrity can be mission-critical, such as aerospace or dental prosthetics.

3. Built for Continuous Operation

Production demands can run around the clock—and so can the ALDC 200. Designed to handle 24 hours of continuous work, this machine reliably powers through long shifts without compromising performance or safety.

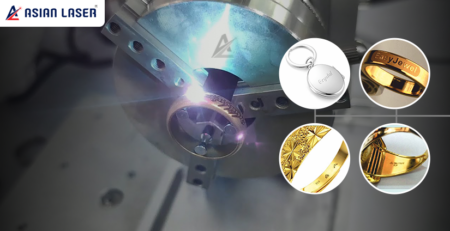

4. Versatility Across Metals and Industries

4.1 Precious Metals: Jewelry, Dentistry

From gold, silver, platinum to palladium, and titanium, the ALDC 200 handles precious metals with finesse. Whether you’re mending a prong, filling porosity, or working near a stone, it achieves seamless results even in delicate, high-value products.

4.2 Industrial Materials: Automotive, Electronics, Healthcare

Its versatility doesn’t end with jewelry. The ALDC 200 also excels in welding applications across various sectors—automotive, solar, electronics, healthcare, hardware, watches, stainless steel fabrication, and dentistry. That breadth makes it a versatile tool in both commercial and industrial settings.

5. Low Maintenance and Environmental Suitability

This laser welding system comes with a reputation for being cost-effective and low-maintenance. Its design optimizes operational efficiency, reduces ancillary costs, and aligns with eco-friendly practices.

6. Ergonomic Productivity: Light Shielding for Safety

Safety and comfort in operation go hand-in-hand. The ALDC 200 is backed with a state-of-the-art light shielding mechanism—a feature highlighted in recent updates—that enhances productivity while ensuring operator safety during intense welding sessions.

7. Quality and Support Infrastructure

7.1 ISO-Certified Reliability

Asian Laser operates under the assurance of ISO 9001:2015 certification, reflecting their commitment to quality and consistency. This lends strong credibility to the ALDC 200 as a durable and trustworthy system.

7.2 24×7 Service and Customization

Alphanumeric design, laser precision—all the stellar technology still relies on support. Asian Laser provides immediate, round-the-clock service, along with customization options tailored to your production needs. That translates to minimal downtime and peak operational efficiency.

Summary: What Makes ALDC 200 Stand Out

Feature

Why It Matters in Precision Metalwork

Minimal heat-affected zone

Preserves delicate shapes and components

Zero deformation

Ensures dimensional accuracy

Deep, firm welds

Reliable, durable joints for critical parts

24-hr operation

Ideal for high-output workflows

Versatile metal compatibility

Great for jewelry, industrial, and medical uses

Low maintenance, eco-friendly

Cost-effective long-term investment

Light shielding

Operator safety and efficiency

ISO certification and 24/7 support

Quality backed by reliable service

FAQs

-

What metals can the ALDC 200 weld?

It handles a wide range—from precious metals like gold, silver, platinum, palladium, and titanium to industrial materials such as stainless steel, electronic components, and more.

-

How does ALDC 200 maintain product integrity?

Its focused laser control minimizes heat spread and warping, protecting the item’s original dimensions.

-

Can the ALDC 200 run all day?

Yes—it’s engineered for 24-hour continuous operation, which makes it excellent for demanding production environments.

-

Is the ALDC 200 safe to use?

Definitely. It includes an advanced light shielding system to protect users, boosting both safety and productivity.

-

What kind of after-sales support is offered?

Asian Laser provides round-the-clock service and options for custom configurations, plus they maintain ISO 9001:2015 standards for quality.