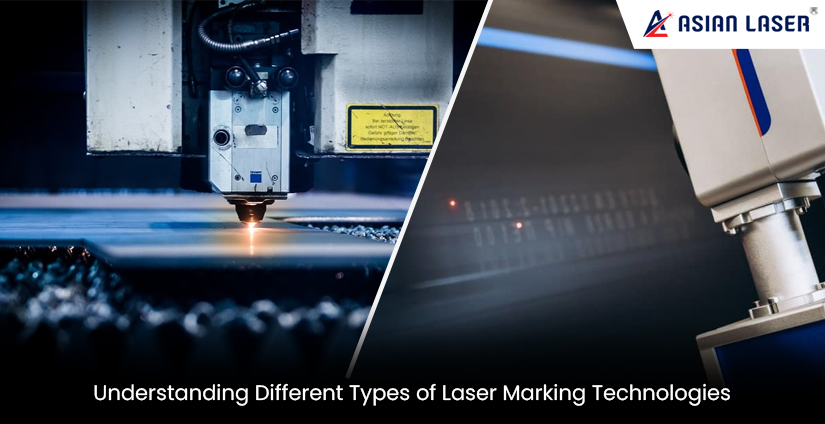

Understanding Different Types of Laser Marking Technologies

Laser marking technology has become an indispensable tool for various industries. From manufacturing and automotive to electronics and jewellery, laser marking offers precise, permanent, and high-quality markings. But with so many different types of laser marking technologies available, it can be overwhelming to choose the right one for your specific needs.

In this blog, we will delve into the different types of jewellery laser marking machines, their applications, and how they can benefit your business. We will also discuss the importance of choosing a reliable laser marking machine manufacturer in India, like Asian Laser, a CE certified and ISO standard company.

- Fibre Laser Marking

Fibre laser marking is one of the most popular laser marking technologies due to its high efficiency, long lifespan, and excellent beam quality. It uses a fibre laser source to generate a high-power laser beam that can mark a wide range of materials, including metals, plastics, ceramics, and glass. Fibre laser marking machines are widely used in industries like automotive, aerospace, electronics, and medical devices.

- CO2 Laser Marking

CO2 laser marking is another widely used technology that employs a CO2 gas laser to generate a laser beam. It is particularly effective for marking non-metallic materials like wood, leather, paper, and certain plastics. CO2 laser marking machines are commonly used in industries like packaging, textile, and advertising.

- UV Laser Marking

UV laser marking utilises a UV laser source to generate a high-energy laser beam with a short wavelength. This technology is ideal for marking delicate materials like plastics, glass, and silicon. UV laser marking machines are widely used in the electronics and semiconductor industries.

- Green Laser Marking

Green laser marking is a relatively new technology that uses a green laser source to generate a high-power laser beam. It offers high precision and speed, making it suitable for marking fine details on various materials, including metals and ceramics. Green laser marking machines are often used in the jewellery and watchmaking industries.

Choosing the Right Laser Marking Technology

When selecting a laser marking technology, several factors need to be considered:

- Material to be marked: Different materials require different laser wavelengths and powers.

- Marking depth and precision: The desired marking depth and precision will influence the choice of technology.

- Marking speed: The required marking speed will determine the appropriate laser power and pulse duration.

- Marking area: The size of the area to be marked will affect the laser beam’s focus and scanning speed.

- Budget: The cost of the laser marking machine and its operating expenses should be considered.

The Importance of Choosing a Reliable Laser Marking Machine Manufacturer

To ensure optimal performance and longevity of your laser marking machine, it is crucial to choose a reputable manufacturer. Asian Laser is a leading laser marking machine manufacturer in India that offers a wide range of high-quality laser marking machines. As a CE certified and ISO standard company, Asian Laser is committed to providing innovative and reliable solutions to meet the diverse needs of its customers.

Conclusion

Laser marking technology has revolutionised the way we mark products and components. By understanding the different types of laser marking technologies and their applications, you can make informed decisions to optimise your marking processes. Remember to choose a reliable laser marking machine manufacturer in India like Asian Laser to ensure the success of your business.