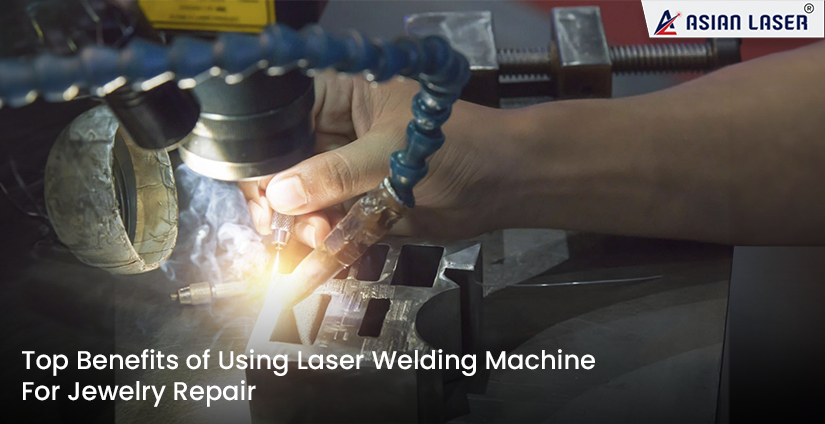

Top Benefits of Using a Laser Welding Machine for Jewellery Repair

In the intricate industry of jewellery repair, precision and efficiency are the top most priority. Traditional soldering methods, while effective, can sometimes be time-consuming and prone to errors. A more modern and efficient approach is gaining popularity: Jewellery Laser Welding Machine. Among laser welding tools, the ALDT 150, ALDC 200 and ALD 200 stand out due to its portability, precision, and versatility.

1. Precision and Accuracy

One of the most significant advantages of using a laser welder for jewellery repair is its exceptional precision. Laser technology allows for highly focused beams, ensuring that the weld is confined to the exact area that needs to be repaired. This precision minimises the risk of damaging surrounding areas or altering the original design of the jewellery piece.

2. Speed and Efficiency

Laser welding is significantly faster than traditional soldering methods. The laser beam can penetrate the material quickly, forming a strong bond in a fraction of the time. This efficiency translates to increased productivity and reduced turnaround times for jewellery repair services.

3. Minimal Heat Affected Zone

Traditional soldering methods can often lead to a larger heat affected zone around the repaired area. This can result in discoloration or weakening of the material. Laser welding, on the other hand, produces a minimal heat affected zone, preserving the integrity and appearance of the jewellery piece.

4. Versatility

Laser welders are incredibly versatile and can be used to repair a wide range of jewellery materials, including gold, silver, platinum, and even titanium. They can handle delicate repairs, such as fixing broken chains or repairing intricate settings, with ease.

5. Portability

Laser welders are designed to be portable, making them ideal for on-site repairs or for small jewellery repair businesses.

6. Cost-Effective

While the initial investment in a laser welder may seem higher than traditional soldering equipment, the long-term benefits can outweigh the cost. The increased efficiency, reduced material waste, and ability to handle a wider range of repairs can result in significant cost savings.

7. Environmental Friendliness

Laser welding is a more environmentally friendly process compared to traditional soldering. It produces fewer fumes and emissions, reducing its impact on the environment.

8. Asian Laser’s Laser Welding Machine ALDT 150, ALDC 200 and ALD 200

Asian Laser, a CE certified and ISO standard company and a leading manufacturer of industrial laser welding machines, offers the Laser Welding Machine ALDT 150, ALDC 200 and ALD 200. This powerful and versatile laser welder is designed specifically for jewellery repair applications. It features a compact design, high precision, and a user-friendly interface, making it a popular choice among jewellers.

Jewellery Laser Welding Machine Manufacturers in India have revolutionised the jewellery repair industry by offering unparalleled precision, speed, and versatility. Their ability to handle a wide range of materials, minimise damage to surrounding areas, and reduce turnaround times make them an invaluable tool for any jeweller. If you’re looking to enhance your jewellery repair capabilities and provide exceptional service to your customers, investing in a laser welder is a wise decision.