Laser Welding: Now Becoming An Innovative Manufacturing Technology

Laser welding machines have evolved as a revolutionary process, pushing boundaries of precision and efficiency. This innovative technique is increasingly being adopted across numerous industries due to its advantages over traditional welding methods.

This article delves into the fundamentals of laser welding, its benefits, applications, and the future it holds in the manufacturing sector.

Understanding Laser Welding

Laser welding is a technique that operates on a concentrated beam of light to connect materials, usually metals or thermoplastics. The laser beam focuses on heat source, allowing for narrow, deep welds and high welding rates. There are two primary types of laser welding:

- Conduction Mode Welding: In this mode, the laser beam heats the material’s surface, melting it and forming a weld. This method is typically used for materials that require high-quality welds with minimal distortion.

- Keyhole Mode Welding: This mode involves the laser beam penetrating the material, creating a keyhole effect. The keyhole is filled with molten material, solidifying to form a strong weld. Keyhole welding is preferred for applications requiring deep penetration and high welding speeds.

Advantages of Laser Welding

Laser welding machines offer several distinct advantages over traditional welding methods, making it an attractive option for manufacturers:

-

Precision and Control

The high precision of laser welding allows for exact control over the welding process. This precision is particularly beneficial in industries where tight tolerances are required, such as aerospace and medical device manufacturing.

-

Speed and Efficiency

Laser welding is usually performed at high speeds, significantly reducing production times. The concentrated heat source also minimises the heat-affected zone (HAZ), reducing the risk of warping or distortion of the materials being welded.

-

Versatility

Laser welding machines can use various materials, including metals, plastics, and composites. It can also weld dissimilar materials, which is often challenging for traditional welding methods.

-

Quality and Strength

The welds produced by laser welding are typically stronger and of higher quality than those made by conventional methods. The process creates a clean, precise weld with minimal spatter and porosity.

-

Automation and Integration

Laser welding machines are highly compatible with automation, making it easily accessible for integration into automated production lines. This integration enhances repeatability and consistency in welding, leading to higher overall product quality.

Applications of Laser Welding

The versatility and efficiency of laser welding have led to its adoption in various industries. Some key applications include:

-

Automotive Industry

Laser welding is widely used in the automotive industry to join components such as gears, transmission parts, and body panels. Its precision and speed contribute to the industry’s high-quality standards and mass production requirements.

-

Aerospace Industry

In aerospace manufacturing, where material integrity and precision are paramount, laser welding is employed to join critical components like turbine blades, fuel tanks, and structural parts. The ability to produce solid and lightweight joints is crucial for the performance and safety of aerospace components.

-

Medical Devices

The medical device industry benefits from laser welding’s ability to create clean, precise welds without contamination. It aids in the production of surgical instruments, implants, and various medical equipment, ensuring high standards of hygiene and reliability.

-

Electronics

In electronics manufacturing, laser welding is used to assemble delicate components and microelectronics. The precision of laser welding ensures minimal heat damage to sensitive parts. Hence, making it ideal for producing high-density circuit boards and other electronic assemblies.

-

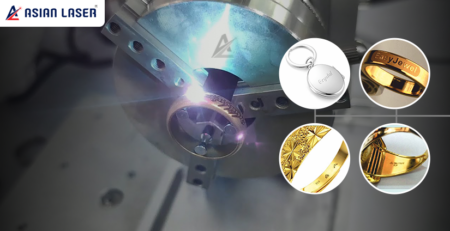

Jewellery and Artisanal Products

The jewellery industry utilises laser welding because it can produce fine, intricate welds on precious metals without damaging the surrounding material. This technology allows jewellers to repair and create delicate pieces with exceptional detail and quality.

Future Trends and Developments

As laser welding technology continues to evolve, several trends and developments are shaping its future in the manufacturing industry:

-

Advancements in Laser Sources

The development of efficient laser sources, such as fiber and diode lasers, is enhancing the capabilities of laser welding. These advancements enable deeper penetration, faster welding speeds, and improved energy efficiency.

-

Integration with Additive Manufacturing

Combining laser welding with additive manufacturing techniques, such as 3D printing, opens new possibilities for producing complex, high-strength components. This integration allows for creating parts with intricate geometries that would be challenging to overcome traditional manufacturing methods.

-

AI and Machine Learning

The use of artificial intelligence (AI) and machine learning into laser welding systems is improving process control and quality assurance. These technologies enable real-time monitoring and adaptive control of the welding process, leading to higher precision and reduced defects.

-

Green Manufacturing

Laser welding is inherently more energy-efficient and produces fewer emissions compared to traditional welding methods. As the focus on sustainable manufacturing practices grows, laser welding is becoming a key technology for reducing the environmental impact of production processes.

-

Expansion into New Materials

Ongoing research is expanding the range of materials that can be effectively welded using lasers. This includes advancements in welding high-performance alloys, composites, and even certain ceramics, broadening the applications of laser welding in various industries.

Laser welding is undeniably transforming the landscape of manufacturing technology. Its precision, speed, versatility, and quality make it an invaluable tool across numerous industries. As technology advances, the potential for laser welding will only grow, driving further innovations and efficiencies in manufacturing processes.

Laser welding presents a compelling and forward-thinking solution for businesses looking to stay competitive and embrace cutting-edge manufacturing techniques.

About Asian Laser

Asian Laser is among the leading laser welding machine manufacturers in India.

Our contribution to technology is revolutionising small business operations. The company is helping small businesses overcome common challenges by offering solutions that enhance precision, efficiency, and customisation.

Asian Laser remains the leading industrial laser welding machine supplier in Mumbai. We are committed to driving innovation and ensuring that the jewellery manufacturing industry can harness the full potential of laser engraving machines for sustained growth and success.

To know about our products and services, connect with us today.