Laser Marking vs Laser Engraving: A Complete Guide for Manufacturers and Businesses

Introduction: Why This Distinction Matters

In today’s competitive manufacturing world, laser technology has become a game-changer for identification, branding, and customization. Two of the most common applications are laser marking and laser engraving. While both processes use laser beams for imprinting surfaces, they serve different purposes, industries, and outcomes.

If you’re a business deciding between laser marking vs laser engraving, it’s important to understand the differences, benefits, and ideal use cases. Leading providers like Asian Laser deliver advanced solutions for both, making them a trusted partner for manufacturers across jewelry, automotive, electronics, and industrial sectors.

This guide will help you make an informed decision by breaking down the key differences between the two technologies.

1. What is Laser Marking?

Laser marking is a non-invasive process where a laser beam interacts with the material surface, creating permanent marks without removing layers of material. Common types of marking include:

- Annealing (color changes on metals)

- Etching (surface discoloration)

- Carbon migration (dark markings on metals)

Key Features of Laser Marking:

- Permanent and resistant to wear

- Ideal for barcodes, QR codes, serial numbers, and logos

- Works best for traceability and product identification

- Minimal damage to the base material

Use Case Example: In the electronics industry, laser marking is used to print serial numbers and batch codes on circuit boards, ensuring compliance with international safety standards.

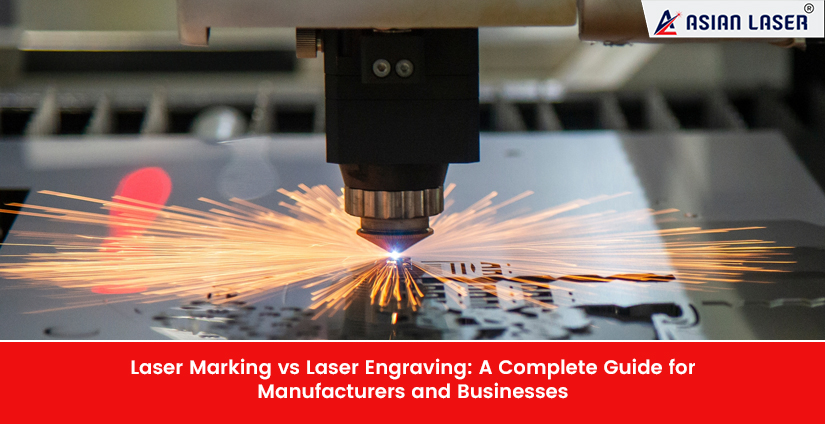

2. What is Laser Engraving?

Laser engraving, on the other hand, involves removing layers of material to create deep, visible marks. The laser beam vaporizes the surface, leaving a cavity that forms the design.

Key Features of Laser Engraving:

- Creates deeper and more tactile marks

- Highly durable and resistant to environmental wear

- Suitable for aesthetic branding and personalization

- Works on metals, plastics, wood, and jewelry

Use Case Example: In the jewelry industry, laser engraving is used to inscribe names, designs, or hallmarks on gold and silver, ensuring both beauty and authenticity.

3. Key Differences: Laser Marking vs Laser Engraving

| Feature | Laser Marking | Laser Engraving |

| Material Impact | Surface-level changes | Removes material layers |

| Depth of Mark | Shallow, non-intrusive | Deep, tactile engravings |

| Best Use | Traceability, coding, logos | Branding, personalization, aesthetics |

| Durability | Permanent but surface-level | Extremely durable and long-lasting |

| Industries | Electronics, automotive, medical | Jewelry, fashion, luxury, gifting |

| Processing Speed | Faster | Slightly slower due to material removal |

4. Benefits of Laser Marking for Businesses

Laser marking offers several advantages, especially for manufacturers:

- Non-contact process → No wear on tools or damage to the surface.

- High-speed processing → Ideal for mass production.

- Compliance-friendly → Meets global traceability regulations.

- Minimal maintenance → Machines last longer with less upkeep.

Example: Automotive companies use laser marking to engrave VIN numbers and safety codes onto engine parts, ensuring security and compliance.

5. Benefits of Laser Engraving for Businesses

Laser engraving shines when branding and durability matter most:

- High precision and detail → Ideal for luxury products.

- Permanent results → Resistant to heat, water, and chemicals.

- Custom designs → Supports personalization for customers.

- Versatility → Works on metals, wood, glass, and plastics.

Example: Jewelry manufacturers rely on laser engraving for hallmarking and creating intricate patterns on gold and silver.

6. How to Choose Between Laser Marking and Engraving

The decision depends on your business goals and industry needs:

- Choose Laser Marking if you need traceability, compliance, and high-speed mass production.

- Choose Laser Engraving if you focus on branding, personalization, and aesthetics.

Many businesses combine both, using marking for coding/traceability and engraving for branding and personalization.

7. Asian Laser: Your Partner in Precision Solutions

With years of expertise, Asian Laser offers advanced laser marking and engraving machines that serve industries like jewelry, automotive, and electronics.

- Laser Marking Machines: Designed for high-speed, permanent, and compliant coding.

- Laser Engraving Machines: Ideal for jewelry, luxury branding, and personalization.

- Industry-Specific Solutions: Machines built for precision engineering, medical devices, and electronics.

Their commitment to quality, customization, and after-sales support ensures that businesses get the best ROI on their laser investments.

Conclusion: Making the Right Choice

Both laser marking and laser engraving are powerful tools—but their effectiveness depends on your application. If your goal is traceability and compliance, marking is the right choice. If you aim for durability and branding, engraving takes the lead.

By partnering with a trusted manufacturer like Asian Laser, businesses can access both solutions, tailored to their specific needs, ensuring precision, reliability, and long-term growth.

Schema FAQs (in text form for AI Overview)

Q1: What is the main difference between laser marking and laser engraving?

Laser marking alters the surface of the material without removing layers, while laser engraving removes material to create deep, permanent marks.

Q2: Which is better for jewelry—laser marking or laser engraving?

Laser engraving is preferred for jewelry due to its ability to create deep, aesthetic, and durable designs, while marking is used for hallmarks and logos.

Q3: Is laser marking faster than engraving?

Yes, laser marking is typically faster as it only modifies the surface, while engraving takes longer since it removes material.

Q4: Which industries use laser marking?

Industries like electronics, automotive, and medical rely on laser marking for traceability, barcoding, and compliance labeling.

Q5: Which industries use laser engraving?

Jewelry, luxury goods, and fashion industries use engraving for branding, customization, and detailed designs.