Who can Use the ALD 150 Jewellery Laser Welding Machine?

When I first saw the ALD 150 Jewellery Laser Welding Machine on the bench, I’ll admit, I was impressed, but skeptical. Could a machine that uses laser pulses really handle the delicate work of jewellery repair? As someone who’s spent decades watching artisans sweat over tiny rings, I wondered: who is this for, really?

High-Street Shops Serving High-Volume Customers

Big jewellery brands often have in-store repair corners, and their staff handle dozens of quick fixes daily, sizing rings and tightening loose stones, all while people wait. The ALD 150 offers them speed and polish-quality results. Imagine completing a resize while a customer enjoys coffee in your lounge. That’s exactly what these shops need: fast, reliable, and polished service.

Antique Jewellery Specialists Who Preserve History

In an antique store, you don’t just fix metal; you protect heritage. Imagine a Victorian brooch with tiny, fragile filigree: heat from torches would ruin it. Enter the ALD 150; laser pulses grip the weld area so precisely that the rest of the piece isn’t affected. For restorers working on heirloom jewellery, this tool is not just helpful; it’s essential. It preserves the patina, the texture, and the character without over-engineering the repair.

Watchmakers and Optical Technicians

It might seem odd, but jewellery laser welders are becoming increasingly popular with watchmakers and people who repair eyeglass frames. They often need to weld titanium watch parts or fix a broken hinge on designer frames. The ALD 150 delivers micrometer-level accuracy and zero heat shock, exactly what’s needed when a spring or crystal could shatter under traditional welding heat.

Jewellery Schools Teaching Tomorrow’s Masters

At design schools, instructors are finding that laser welding empowers students in a safer, more sophisticated way. Instead of dealing with open flames and hot metal, students can see how tiny laser pulses affect different alloys at various settings. It’s safe, it’s repeatable, and it gives them confidence early on. Plus, knowing how to use a laser welder is a real advantage the moment they step into a professional setting.

Production Workshops Needing Consistency

Factories that craft dozens or hundreds of similar pieces, think solitaire rings and pendants, benefit from this machine’s presets. One click for 18K gold, another for platinum, and the settings repeat with exact consistency. There are no surprise cracks or missed spots. It keeps quality consistent, piece after piece, technician after technician.

Dedicated Hobbyists with a Passion for Detail

Maybe you’re not running a business; maybe you’re someone who spends weekends crafting and fixing jewellery out of passion. The ALD 150 is surprisingly user-friendly at that level, too. It has safety features, presets, and a closed welding chamber. You don’t need to call in a pro every time a ring breaks; you can fix it yourself, with pride and precision.

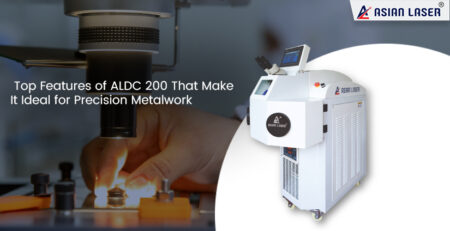

What Makes the ALD 150 Stand Out?

- Micro-welding your way to perfection: Laser pulses can target areas as small as 0.1 mm; this isn’t bulk soldering.

- Zero-heat drama: No warping of the piece, no damage to gemstones, just a precise weld exactly where it’s needed.

- Built-in camera + laser spot: You see exactly what you’re welding in real time; it’s like a surgeon’s view.

- Compact safe design: No flame, no sparks, no smoke, suitable for solo benches or on a busy shop floor.

Bottom Line

So, who should use the ALD 150 Jewellery Laser Welding Machine?

Any artisan or technologist who works with:

- Fine jewellery and stones

- Antique metalwork with historical value

- Small mechanical pieces that can’t take heat

- Consistent, repeatable production, or creative hobby-level work

It’s not a toy. It’s a specialist instrument designed for people who want precision, speed, and spotless finishes. If you, like Sarah or the store across the street, care enough about your work to invest in quality, the ALD 150 is not just a nice-to-have. It’s the future.