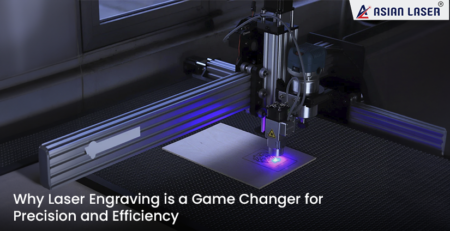

How to Optimize Your Laser Engraving Machine for Maximum Efficiency

The importance of efficiency cannot be overstated. Optimising your equipment can substantially enhance your productivity and financial performance. This is especially true for laser engraving machines for metal and other objects. These versatile tools can be used for a wide range of applications, from creating personalised gifts to industrial manufacturing. However, to maximise their potential, it’s essential to optimise them for maximum efficiency.

- Understanding Your Laser Engraving Machine

Before diving into optimization techniques, it’s crucial to understand your laser engraving machine. Different machines have different capabilities and limitations. Familiarise yourself with your machine’s specifications, including its power output, laser type, and engraving speed. This knowledge will help you tailor your optimization strategies.

- Regular Maintenance

Just like any other machine, a laser engraving machine requires regular maintenance to function optimally. Here are some essential maintenance tips:

- Clean the Lens: A dirty lens can significantly reduce the quality of your engravings. Clean it regularly with a lens cleaning solution and a soft cloth.

- Check the Cooling System: Ensure the cooling system is working properly to prevent overheating.

- Lubricate Moving Parts: Regularly lubricate moving parts to reduce friction and wear.

- Calibrate the Machine: Calibrate your machine periodically to ensure accurate engravings.

- Optimising Laser Parameters

Laser parameters, such as power, speed, and focus, play a crucial role in the quality and efficiency of your engravings. Experiment with different settings to find the optimal combination for your specific materials and applications.

- Power: The power setting determines the intensity of the laser beam. A higher power setting is typically required for thicker materials or deeper engravings.

- Speed: The engraving speed affects the quality and detail of the engraving. A slower speed produces higher-quality engravings but takes longer.

- Focus: Proper focus is essential for achieving sharp and precise engravings. Adjust the focus to ensure the laser beam is concentrated on the material.

- Choosing the Right Materials

The type of material you use can also impact the efficiency of your laser engraving process. Some materials are more easily engraved than others. Consider factors like material thickness, heat sensitivity, and surface finish when selecting materials.

- Software Optimization

The software you use to control your laser engraving machine can significantly impact your workflow. Choose software that is user-friendly and offers a wide range of features, such as vector graphics editing, image processing, and automatic job scheduling.

- Efficient Workflows

To maximise efficiency, it’s important to establish efficient workflows. Here are some tips:

- Organise Your Workspace: Keep your workspace clean and organised to minimise downtime.

- Batch Processing: Process multiple jobs simultaneously to save time.

- Automate Tasks: Use automation tools to streamline repetitive tasks.

- Optimise Material Handling: Develop efficient methods for loading and unloading materials.

- Investing in Quality Equipment

Investing in a high-quality laser engraving machine can pay dividends in the long run. Look for machines with advanced features, such as automatic focus, variable power output, and high-speed engraving.

- Partner with a Reliable Supplier

Choosing a reliable supplier is essential for ensuring the long-term performance of your laser engraving machine. Asian Laser, a leading CE certified and ISO standard compliant laser engraving machine manufacturer in India, offers a wide range of high-quality machines.

Conclusion

By following these tips, you can optimise your laser engraving machine for maximum efficiency. Remember, understanding your machine, performing regular maintenance, and experimenting with different settings are key to achieving the best results. By investing in quality equipment and partnering with a reliable supplier like Asian Laser, you can take your laser engraving business to new heights.