The Purpose and Importance of a Laser Engraving Machine

In the contemporary technological and crafts landscape, the laser engraving machine stands out as a remarkable tool. Its ability to precisely etch designs onto various materials has revolutionised industries ranging from manufacturing to art.

Understanding the purpose and importance of a laser engraving machine reveals why it has become indispensable in modern practices.

What is a Laser Engraving Machine?

The laser engraving machine engraves or marks objects using laser technology. Unlike traditional engraving methods that rely on physical contact, laser engraving is a non-contact process that employs a high-powered laser beam. This beam is directed at the material’s surface to remove or vaporise the material, leaving behind a permanent mark.

Why is Laser Engraving Important?

Laser engraving’s importance lies in its versatility, precision, and efficiency. This versatility makes it suitable for various industries, from manufacturing to personalised gifts.

The precision of laser engraving is unmatched. The laser beam can create detailed patterns and designs with micron-level accuracy. This precision is essential for applications requiring fine details, such as intricate jewellery designs, circuit boards, and medical devices.

Efficiency is another crucial factor. Laser engraving is a fast process that can produce high-quality results with minimal waste.

What is the Application of Laser Engraver?

The applications of laser engravers are vast and diverse. In the manufacturing industry, laser engravers are used to mark parts with serial numbers, barcodes, and logos. This is crucial for traceability and quality control.

For example, in the automotive industry, parts are often laser engraved with identification codes to track their production history and ensure they meet safety standards.

In the electronics industry, laser engraving marks circuit boards with detailed information. This is important for identifying components and ensuring they are correctly assembled. The precision of laser engraving is essential in this field, where even the slightest error can lead to malfunctions.

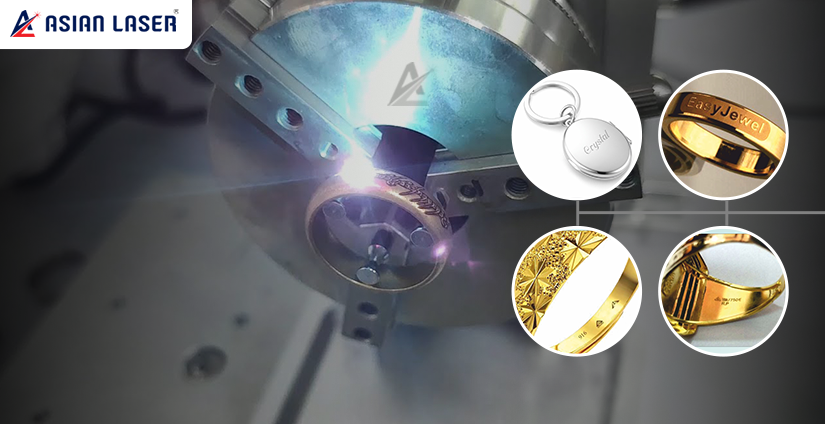

The jewellery industry also benefits significantly from laser engraving. Engraving intricate designs and personal messages on precious metals, such as gold, is common. For instance, laser engraving on a gold ring allows for highly detailed and personalised inscriptions that enhance the item’s value and sentimental significance.

Laser Engraving Machine Uses

Laser engraving machines have found their way into many fields due to their versatility. In addition to manufacturing and electronics, they are widely used in the medical industry. Medical devices are often laser engraved with unique identifiers to ensure traceability and compliance with regulatory standards.

The arts and crafts sector also extensively uses laser engraving machines. Artists and designers use them to create detailed patterns on various materials, from wood to leather. This has opened new avenues for creative expression, allowing artists to produce intricate designs that were previously impossible or too time-consuming to achieve by hand.

Laser engraving machines are invaluable in the realm of personal and corporate gifts. They enable the customisation of items like pens, keychains, and trophies, making them unique and memorable.

This personalisation aspect is prevalent for corporate branding and special occasions like weddings and anniversaries.

What is Laser Engraving on a Gold Ring?

Laser engraving on a gold ring exemplifies the machine’s precision and personalisation capabilities. Gold, a soft and malleable metal, is ideal for laser engraving. The laser can create detailed designs, intricate patterns, and even tiny text without damaging the ring’s surface.

This method is preferred over traditional engraving because it produces cleaner lines and allows for more complex designs.

Personalising gold rings with laser engraving has become a popular trend for wedding bands, engagement rings, and anniversary gifts. Couples often engrave their names, special dates, or meaningful symbols on their rings.

The durability of laser engraving ensures that these engravings last a lifetime, adding sentimental value to the jewellery.

The Future of Laser Engraving

The future of laser engraving looks promising as technology continues to advance. Innovations in laser technology are making machines more affordable and accessible, even for small businesses and hobbyists. As a result, we can expect to see even more creative and practical applications of laser engraving in various fields.

One exciting development is the integration of laser engraving with computer-aided design (CAD) software. This allows for greater precision and the ability to produce complex 3D engravings. Additionally, advancements in laser power and wavelength control enable engraving on even more materials, further expanding the potential applications.

Sustainability is another area where laser engraving is making strides. As industries move towards more environmentally friendly practices, the efficiency and minimal waste production of laser engraving align well with these goals.

The ability to engrave without the need for inks or chemicals makes it a cleaner option compared to other marking methods.

To Conclude:

The purpose and importance of a laser engraving machine are evident in its wide-ranging applications and the benefits it offers. From precision and efficiency to versatility and personalisation, laser engraving has transformed how we mark and customise materials.

Whether it’s for industrial, medical, artistic, or personal use, the laser engraving machine continues to be a valuable tool that enhances quality, creativity, and functionality. With technological advancement, the capabilities and applications of laser engraving will only continue to grow, solidifying its place as an essential tool in various industries.