How Technology is Revolutionising the Jewellery Manufacturing Industry

In India, jewellery is considered more than just an accessory. Be it style statements or financial security; people invest in ornamental jewellery to a greater extent. But, how can jewellery adapt to the evolving preferences and expectations of contemporary consumers?

It’s the power of technology that revolutionaries the jewellery manufacturing process. From 3D design to virtual reality and blockchains, technology plays a significant role in unlocking creativity, productivity, and trust in the jewellery industry.

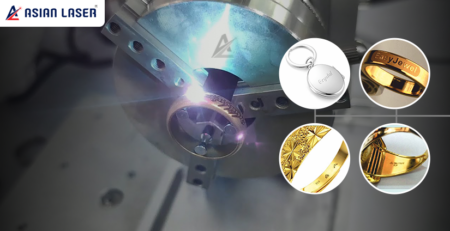

Traditional craftsmanship is now seamlessly blending with cutting-edge innovations, ushering in a new era of precision. Jewellery Laser Welding Machines, for instance, offer the most advanced light shielding system that reduces irritation to the eyes and repairs casting defects without removing the stones.

This article addresses different ways in which technology is revolutionising the jewellery manufacturing industry, from design to production.

Technology in Jewellery Industry

Studies state the jewellery market will grow from 270 billion U.S. dollars in 2022 to 330 billion U.S. dollars by 2026. And it will be only possible with continuous upgradation in the jewellery manufacturing process.

Here are some technological advancements that are used in the manufacturing process of jewellery industry.

-

Digital Design and 3D Printing

The jewellery makers tend to create unique, stunning ornaments that appeal to the customers. However, it’s challenging to keep creating new designs without knowing the preferences of the final users. This is where digital design and 3D printing come into the picture.

The jewellery designers use sophisticated software in the jewellery manufacturing process to create intricate and detailed designs with precision. 3D printing allows for quick prototyping of designs, enabling designers to bring their visions to life in a matter of hours rather than weeks.

Some famous 3D printing programs include Rhino3D, Jewelry CAD Dream, Blender and MatrixGold. These technologies provide built-in tools to test variations and material simulations that are only possible digitally.

-

Augmented Reality (AR) in Customization:

Immerse technologies like augmented reality (AR) allow consumers to try digital jewellery from their comfort space. Interactive 3D models topped over real-time video enable them to customise their jewellery in the way they like.

Furthermore, augmented reality (AR) enhances the customer experience while boosting confidence to buy jewellery online. From engraving a quote to selecting different designs, technology in jewellery industry has expanded business activities to the next level.

Many renowned jewellery brands are undertaking immersive digital experiences like 3D environments to engage customers. Also, the rise of e-commerce has reshaped the way consumers buy jewellery. Online platforms leverage technology to provide immersive virtual shopping experiences.

-

Blockchain for Transparency

Finance management plays an imperative role in the jewellery manufacturing process. And small jewellers have limited access to capital as most transactions are done in cash. This prevents them from reporting the full extent of their turnover into accounts, further violating transparency measures and regulations.

By utilising blockchain, manufacturers can create an immutable record of the entire supply chain, providing consumers with detailed information about the origin of the materials used in their jewellery. This fosters trust and ensures ethical practices are adhered to.

Today, jewellers can tokenise gold and other precious metals using blockchain. These digital tokens represent a specific amount of physical gold or metal, which are further used as a form of collateral to access loans from lenders.

-

Robotics in Manufacturing:

Robotics is revolutionising the manufacturing process by increasing efficiency and precision. Automated systems are being employed for tasks such as soldering, stone setting, and polishing.

AI is making significant strides in automating and enhancing various aspects of jewellery manufacturing. From predicting design trends based on market data to optimising production processes, AI is streamlining operations and reducing costs. In production, AI is being used to improve precision in gemstone cutting, leading to higher-quality finished products.

These robotic systems can handle repetitive tasks with unparalleled accuracy, allowing skilled artisans to focus on more intricate and creative aspects of jewellery making.

Conclusion:

Technology is not just changing the face of the jewellery manufacturing industry; it is sculpting its future. From digital design tools to blockchain transparency, the integration of technology is fostering a dynamic and innovative environment.

This revolution is reshaping production processes and redefining the relationship between artisans, designers, and consumers. As technology continues to evolve, the jewellery manufacturing industry is set to dazzle the world with even more brilliance and creativity.

FAQ

Q1: How does technology fit into the jewelry-making process?

A1: Precision and efficiency are improved by technology, from design to production, which results in improved quality and innovation.

Q2: What effects has 3D printing had on the production of jewellery?

A2: 3D printing revolutionises conventional production processes by enabling complex designs and quick prototyping.

Q3: Is it possible for technology to enhance jewellery customisation?

A3: Without a doubt, technology makes it possible to create unique designs and bespoke items that easily suit each person’s preferences.

Q4: What benefits do technological innovations provide for sustainability?

A4: Technology promotes sustainable behaviours by cutting waste, optimising the use of resources, and using eco-friendly products.

Q5: What are the difficulties in incorporating technology into the jewellery-making process?

A5: Adapting to ongoing technological improvements and providing qualified workforce training are challenges.