Why laser marking outperforms inkjet

Product and component manufacturers are aware that marking their appliances with a barcode, model number, part number or logo is very crucial. Marking the apparatus makes it extremely convenient for suppliers and customers to identify components in case of future replacement and repair. Amidst all the different methods of marking, a conventional technique has been through printing labels. Printing labels have been widely favoured to use but have their downsides to laser engraving. Laser engraving triumphs in endurance and cost over printing methods. Laser engraving is the most efficient tactic amongst all the other practises out there. It is necessary to understand what laser marking machines offer to overcome printing instruments substantially.

What is laser printing?

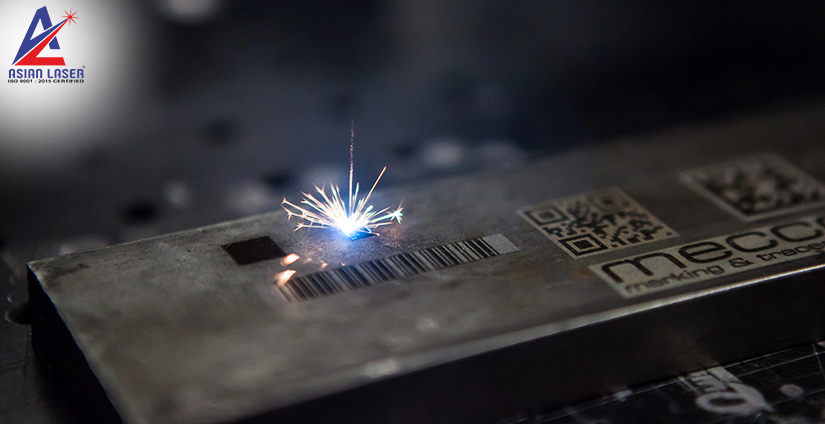

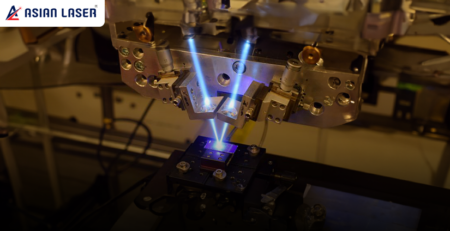

When the laser light is focused on a material, it produces a profound or contrasting mark varying on the settings being used. Laser engraving does not disseminate any ink or substance on the surface of the material. Neither does Laser engraving entail a physical tool that etches the surface. There are a plethora of laser marking machines that can be used to execute a given endeavour. The assortment incorporates various devices ranging from low power desktop machines ideal for small quantities, to fully unified units within a production line. The laser marking approach can outclass a printer with more attractive markings and everlasting results. Laser marking is ideal for equipment and tools that need a long-lasting tag for exclusive representation.

The advantages of laser marking over an inkjet,

- Longevity of use

Laser marking machines provide a permanent mark that is absolutely inedible. The marking from laser printing machines lasts as long as the surface integrity of the substrate. In the case of inkjet, the ink must be baked on the substance after the marking is concluded. The marking made by inkjet is not entirely secure and can be rubbed off in time.

- Speed

Laser engraving machine can mark with rates of more than 100 characters/second in specific cases. The speed of laser marking machines helps in improving efficiency and decreases the time taken to etch various products. In the case of inkjet, vital procedures generate prolonged cycle times for any given substrate.

- Precision

The printing precision in laser marking machines is exceptionally high. The control is accurate, and the printing content is clearly and correctly comprehended. The laser can be marked on the product material with a thin beam. It is significantly robust when compared to its counterparts. Laser marking machine can print a large amount of data in a minimal radius. Laser marking has special protection for operators, ensures uncluttered production sites, reduces post-investment and cuts down on noise pollution.

- Environment-friendly

Laser marking machinery requires no consumables. These machines run off a standard 110v outlet. Inkjet, on the other hand, has a constant need to replace inks that are used in the process. Printing through inkjet also creates a lot of waste resource. Inkjet is thus expensive to use and even harder on the environment.

The only benefit inkjet has over laser marking machine is that it provides full RGB or CMYK colour bands. This quality can be beneficial in fabrics. Laser marking machines provide grayscale markings only.

In conclusion, laser marking is the far better solution for direct part marking as it is faster, permanent and has a low cost of ownership overall. Without any use of consumables, it even assures that the marking stays well intact in the absence of any additional processes.