Advantages of using jewellery laser engraving machines for your jewellery business

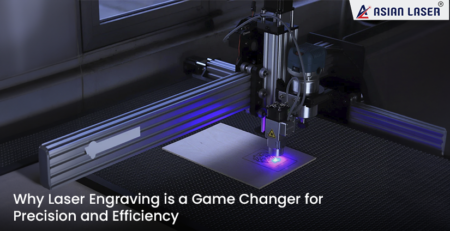

Laser engraving machines can interface with computers, permitting the client to format configuration, embed type and scale the craftsmanship as required. If perfectly set up, the device can create a design flawlessly, and repeat the process as many times as required. Laser engravers can work on a variation of materials which includes wood, plastic, paper and aluminium. The method is moderately quick and involves experience but not a great deal of skill, even though the level of detail and accuracy in the output may be at a very high standard.

In contrast, traditional engraving is completed with small handheld engraving tools, all of which must be thoroughly sharpened. Hand engraving is slow and difficult and is mostly done on metal. Laying out a picture, with or without illustrations or type, is tedious and difficult. Often, a laser engraver must practice for years to perfect his craft. But although the work is difficult, the results are undoubtedly beautiful, whether as simple as an engraved wedding ring or as complicated and delicate because of the portrait. The road condition is superior because hand tools are often established so well. An engraver can make thick lines, thin lines and also fine lines.

As you will see, the fabric opportunities are wide-ranging, with many of these listed above commonly employed in various pieces of jewellery. So if you are an engraver or have a business that produces jewellery, you will see why laser engraving systems might be relevant to your company and for your customers.

Some of the significant advantages of employing a laser engraving machine for jewellery include:

Precision – Laser markers can accommodate exacting, micron-level accuracy that’s repeatable, ensuring that any product that’s engraved features a result that’s definitely what it’s asserted to be.

Speed – Our practices offer an extension in rate over many other methodologies, particularly hand engraving.

Quality – The ultimate marks and engravings that are made through Asian Laser systems are fresh, crisp, and designed to last.

Reduced Costs – Since laser marking requires no consumables, and doesn’t get to have parts like styluses regularly replaced, they’re a worthwhile long-term investment.

You can learn more about the laser marking process and the way it stands out from other marking and engraving techniques on our technologies blog post.

Because of these advantages, you will be ready to comfortably engrave rings, necklaces, bracelets, watches, earrings, or the other piece a customer might want. This may allow you to supply options for:

- Names and initials

- Signatures

- Personal or inspirational quotes

- Important dates

- Family photos

And alongside everything possible by way of alphanumeric characters, jewellery laser engraving machines from Asian Laser can promote designs with expertise since everything is often preprogrammed into the system. This may allow you to offer:

- Logos

- Crests and coats of arms

- Graphics and special designs

- Pictures of loved ones

It is said that the sky’s the limit when it involves laser marking jewellery!

Asian Laser offers an excellent array of laser engraving machines for jewellery with diverse functionalities. These units are often incorporated into factory operations or housed in small shops with ease, based on the model.

Are you looking to Laser Engrave Jewellery? Connect with Us!

If you think that Asian Laser is ideal for your operations and your customers, make sure to contact us today. We’ll assist you in assessing your needs and determining the most straightforward jewellery laser marking system for your company!